If you a piano owner, and especially if you own an older piano, it is likely you have experienced so called “sticking keys”. This is a catch all term which describes any situation where the key does not play properly. This typically is a mechanical issue involving the moving parts inside the piano which is not in any way connected with the tuning.

There are many kinds of sticking keys. A key may sag halfway down. The key itself may move normally, but when you press it sometimes it does not make a sound. Sometimes this only occurs on a loud forte blow, not on a soft blow.

While it may seem like a straightforward thing to fix, there are dozens of different reasons which might be the cause and it requires an adept piano technician to quickly diagnose the problem. Listed below are many of the common causes.

* NEVER try to lubricate piano parts yourself with over the counter lubricant sprays such as WD-40. Consumer products will spread lubricant all over the piano potentially ruining the pin block (the pins hold the strings in place), thus ruining the instrument. Piano technicians use a special silicone based lubricant called Protek which is applied very carefully with a needle.

1) The front rail bushings are too tight due to age, humidity, or poor construction. The front of the key has a slit in the bottom which is lined with felt. This moves up and down on a metal pin. The hole can sometimes become tight, causing the key to become sluggish. This is very common for those who live near the ocean. This is the easiest and cheapest problem to fix. The technician simply squeezes the key opening with some special pliers to enlarge it.

2) The balance rail bushings are too tight. The balance rail is further back where the center of the key is located. Similar to the above problem this is an easy fix.

3) The key leads are bulging and rubbing on their neighbors. This is typically only happens to pianos in a humid environment or to lesser quality instruments. Piano keys have lead weights inside them. If the wood swells due to high humidity, which happens a lot if you live near the ocean, it squeezes the lead causing it to protrude from the sides of the key. The effect is like squeezing a tube of toothpaste. The solution is to remove the keys and chip off the excess lead with a chisel. This is a fairly time consuming fix, especially on grand pianos.

4) The key is rubbing on its neighbor. This can easily be tested by removing the neighbor keys. The fix is to better align the keys to avoid collision. Rarely one might have to sand the sides of the key with sandpaper.

5) A foreign object is between the piano keys. This one behaves a lot like #4. The solution is to remove the key. Either the foreign object can then be removed or it just drops down naturally. The most common objects are quarters, paperclips, and rodent droppings.

6) There is a foreign object on top of the keys. Clues to this problem are strange noises emanating from the keys, and also if all the keys in the same area stick. Also an easy fix. Simply remove the object.

7) The whippen flange is sluggish. The whippen is a complex part that allows the hammers to rebound off the strings. It is what made the piano a revolutionary invention in the 1700’s. This is the first part the key comes in contact with when you press it. If it becomes sluggish, the note will not repeat. That means you can play it once, but the second time it may not make a sound. Because this part is not easy to access, typically the action must be removed from the piano. Removing the action is easy on an upright and only slightly more difficult on a grand. On spinet pianos, the amount of time required usually means its not worth it. The easy solution is to lubricate it. If that doesn’t work, it must be repinned.

8) The jack is sluggish. The jack is a letter L shaped piece attached to the whippen. Similar to the whippen flange, the solution is to lubricate it, then if that fails repin it.

9) The jack spring is weak or broken. This is a very uncommon scenario. Usually another issue is the cause.

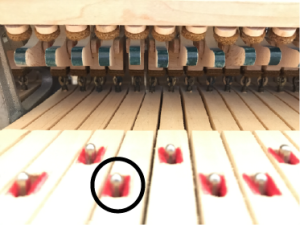

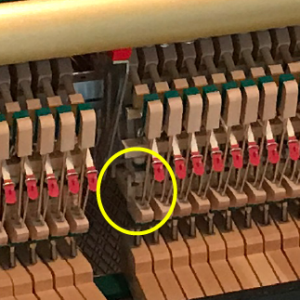

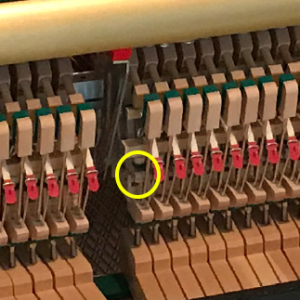

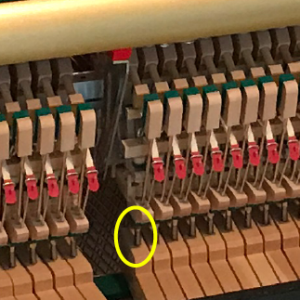

10) The jack is making contact with the jack stop rail. This produces a very mysterious symptom in upright pianos in which the key is released, drops back down, but the whippen and jack stay frozen in the air. The solution, known to only a few technicians, is to move the jack stop rail forward.

11) The capstan is too high, meaning there is no lost motion between the jack and the hammer. The capstan is a brass knob on the back of the key. It is used to adjust how soon the key should start moving the hammer when you press down. Typically it should move an almost imperceptible amount before the hammer begins to move, meaning there is a very tiny gap. This gap allows the jack to reset when they key is released. If adjusted too high, the jack can’t slip back under the hammer when it is done. The solution is to turn the capstan a few strokes clockwise.

12) The hammer flange is sluggish. This is easy to identify. The piano technician pushes the hammer forward with his hand. If it doesn’t return, the flange is too tight. This is caused by high humidity, age, and less commonly by corrosion of the center pin called “filigree”. It is common for those who live in humid areas. The solution is to lubricate it, and then repin if needed. On some pianos, the hammer has a screw allowing it to be adjusted. The hammer is removed, adjustments are made, then the hammer is replaced. Yamaha U1 pianos have this system.

13) The hammer return spring is misplaced. Often on older pianos, the spring that helps the piano to its resting position can become disconnected. The solution is to use a special tool to reseat it. Sometimes if the spring is bent, it must be straightened.

14) The hammer return spring is missing. This is a more complex situation which requires removing the action and inserting a new spring.

15) The key slip is rubbing on the key. The key slip is the small piece of wood in front of the keys that hides the key bottom from view. Usually on grand pianos this may be too close to the keys causing the keys to make contact. The solution is to “shim” the keyslip, meaning to insert a business card thus pushing it outward. Rarely there will be screws that one can use to adjust it.

16) The hammer is misaligned and is rubbing on its neighbor. This is a very common issue. If the hammer is not straight, it may touch the hammer next to it, causing both to get stuck. The solution is to loosen the hammer screw, reposition, then tighten. Sometimes a tiny strip of adhesive paper must be added to change the hammer angle. If the hammer is severely out of alignment, sometimes heat must be applied with a heat gun so the wood can be twisted and reshaped.

17) Missing hammer head. In this case, the note will not make any sound whatsoever. The good news is that the hammer head often falls inside the piano somewhere. Amazingly, these can usually be glued back on with wood glue, or sometimes a viscous type of CA glue. The hammer needs to be filed after this to ensure the grooves aren’t misaligned with the string. Piano owners should not attempt to fix this themselves.

18) The Hammerhead wool has become detached. Hammerheads are made of wool which is attached to the hammer under high pressure. If it becomes detached, there is no effective way to attach it. However, your piano technician can prevent it from rubbing on its neighbors by filing it with sandpaper. The piano will still play but the sound will be weaker. This is very common in Baldwin pianos located in humid environments. If you own a Baldwin piano near the ocean, it is important to have your technician install a humidity control system to prevent this.

In short, there are many reasons that a piano key can stick. Contact L.A. Piano Tuning and we can help you resolve your issue quickly and painlessly.